Flowmeters

Paddlewheel Flowmeters

Blue-White paddlewheel flowmeters are designed to be inserted into closed fluid systems to monitor flow. The paddlewheel sensor relays flow information to either an LCD digital display screen, or through wiring to user provided equipment.

BW DIGIMETER® offer output capabilities for batch processing and proportional feed control.

BW DIGI-METER® Paddlewheel Flowmeters

- Battery or AC powered digital paddlewheel flowmeters

- Pipe Sizes 3/8″ to 12″

- Functions Include: Rate, Total, Analog Output, Batch Processing, Flow Rate Alarm

F-2000 Digital Paddlwheel Flowmeter

- Water Ranges: 0.4 to 8000 GPM (1 to 27000 LPM)

- Pipe Sizes: ⅜”, up to 12″

- Sensor, Pipe, Panel or Wall mount options available. Up to 200ft. range

Product description:

- Easy to read 8 digit LCD, up to 4 decimal positions

- Flow rate and Total flow display

- AC/DC transformer or battery operated (RT models only). 4 AA batteries

- Factory programmed with calibration certificate

- Front panel security lockout

- Total reset function can be disabled

- Weather resistant ABS enclosure. NEMA 4X

- Panel mounting option available (ships with 25ft of cable)

- Custom calibration units available. Contact the factory

- Standard models ship with pipe fitting

Note: LCD is not recommended for direct sunlight applications.

F-1000 Digital Paddlewheel Flowmeter

- Water Ranges: 0.4 to 8000 GPM (1 to 27000 LPM)

- Pipe Sizes: ⅜”, up to 12″

- Sensor mounted on pipe fitting. Battery operated

Product description:

- Easy to read 6 digit LCD, up to 4 decimal positions

- Battery Operated (2 AAA batteries included)

- Acceptable for Vertical or Horizontal installation

- Total Reset function can be disabled

- Display update time: Rate 1.5 sec., Total 0.5 sec

- Factory calibrated – Nothing to program

- NEMA 4X weather resistant enclosure

- LCD not recommended for direct sunlight exposure

- Standard Models ship with pipe fitting included

MICRO-FLO

- Water Ranges: 0.47 to 110.9 GPH (30 to 7000 mL/min)

- Pipe Sizes: ⅛”, ¼”, ½” NPT

- ¼” and ⅜” OD Tubing

Panel, Pipe or Sensor Mount

MICRO-FLO FOR LOW-FLOW MONITORING APPLICATIONS

Acceptable for Vertical or Horizontal installation

Electronics:

- 9-28 VDC input power required (AC/DC transformers available)

- Factory calibrated – Nothing to program

- Non-Volatile programming and accumulated flow memory

- Total Reset function can be disabled

Display:

- Displays both rate of flow, and total accumulated flow

- Easy to read 6 digit LCD, up to 4 decimal positions

- LCD not recommended for direct sunlight exposure

- User Selectable or custom programmable scale factors:

- Flow Units: Gallons, Liters, Ounces, Milliliters

- Time Units: Minutes, Hours, Days

Communication:

- Open collector alarm set point

- Output signal: digital pulse output (2 wire)

Construction:

- Infra-red light sensor

- Clear PVC viewing lens or PVDF chemical resistant lens

- NEMA 4X weather resistant enclosure

Model Variations:

- FA = Analog Output. Rate & Total. Sensor Mounted Display

- FS = Rate & Total. Sensor Mounted Display

- FP = Rate & Total. Panel Mounted Display

- FV = No Display, Sensor Only. 5 VDC current sinking output (includes 6ft. cable)

- FX = No electronic sensor. Visual indicator only

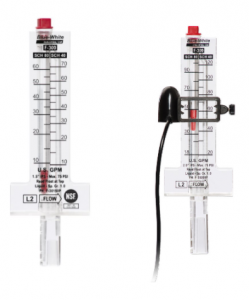

Variable Area Flowmeters

Dependable flow monitoring, every time

The variable area line of flowmeters include velocity driven float and scale type meters.

Meters require in-line or panel mounted, vertical installation. Both gas and fluid models are available.

Variable Area Flowmeters:

- Direct reading variable area flowmeters

- Available in Machined Acrylic and Molded Polysulfone Materials

Acrylic Models – Suitable For Direct Sunlight

F -300 ACRYLIC FLOWMETER

Model Variations:

- F-300 = Horizontal flow

- D-300 = Vertical down flow

- U-300 = Vertical up flow

♦ Pipe sizes: 1″, 1¼″, 1½″, 2″, 2½″, 3″, 4″, 6″, 8″

♦ Flow from: 4 to 1900 GPM (15 to 7200 LPM)

♦ Clamp-On – Insertion Mount

Description:

- Well suited for closed pipe installations

- Easy to read dual scale (GPM / LPM), screen printed on both sides of the meter body

- Acceptable for outdoor installations (direct sunlight okay)

- Pitot Tube (impact tube) design makes it easy to install on existing pipe

- One piece, machined acrylic meter body, annealed for added strength and chemical resistance

- Included SS clamps and gasket seal

- Standard and Low Flow options available

F-400 ACRYLIC FLOWMETER

- Pipe sizes: 1/4″, 3/8″ and 1/2″ F/NPT

- Flow from: 0.025 to 5 GPM (0.1 to 20 LPM)

- Acceptable in Direct Sunlight

Description:

- Durable, highly polished, one piece meter body

- Annealed for added strength and chemical resistance

- Acceptable for outdoor installations (acceptable in direct sunlight)

- Direct reading permanent scale

- White back reflector for easy reading

- Standard 316 stainless floats and guide rods, optional Hastelloy-C for more corrosive environments

F-410N ACRYLIC FLOWMETER

- Pipe sizes: 3/4″ and 1″ F/NPT

- Flow from: 1 to 20 GPM (4 to 80 LPM)

- Acceptable in Direct Sunlight

Description:

- Durable, highly polished, one piece meter body

- Annealed for added strength and chemical resistance

- Acceptable for outdoor installations (acceptable in direct sunlight)

- Direct reading permanent scale

- White back reflector for easy reading

- Standard 316 stainless floats and guide rods, optional Hastelloy-C for more corrosive environments

- High/Low Alarm models available

F-420N ACRYLIC FLOWMETER

- Pipe sizes: 1″ female NPT fittings 1 1/2″ male NPT fittings

- Flow from: 5 to 25 GPM (20 to 100 LPM)

- Acceptable in Direct Sunlight

Description:

- Durable, highly polished, one piece meter body

- Annealed for added strength and chemical resistance

- Acceptable for outdoor installations (acceptable in direct sunlight)

- Direct reading permanent scale

- White back reflector for easy reading

- Standard 316 stainless floats and guide rods, optional Hastelloy-C for more corrosive environments

F-430N ACRYLIC FLOWMETER

- Pipe sizes: 1 1/2″ and 2″ female NPT fittings

- Flow from: 4 to 100 GPM (15 to 375 LPM)

- Acceptable in Direct Sunlight

Description:

- Durable, highly polished, one piece meter body

- Annealed for added strength and chemical resistance

- Acceptable for outdoor installations (acceptable in direct sunlight)

- Direct reading permanent scale

- White back reflector for easy reading

- Standard 316 stainless floats and guide rods, optional Hastelloy-C for more corrosive environments

F-550 ACRYLIC FLOWMETER

- Pipe sizes: 1/4″, 3/8″, 3/4″ and 1″ male NPT 1/2″ hose barb

- Flow from: 0.025 to 20 GPM (0.1 to 75 LPM)

- Panel Mount Adjustable Valve Available

Description:

- Durable, highly polished, one piece meter body

- Annealed for added strength and chemical resistance

- Acceptable for outdoor installations (acceptable in direct sunlight)

- Bulkhead nuts attach directly to inside panel

- Optional adjustable flow control: needle-type adjustment valve

- Direct reading permanent scale

- White back reflector for easy reading

- 316 stainless, PTFE or Hastelloy floats and float guides

Variable Area Flowmeters High Temp / High Pressure Models

Not Recommended For Direct Sunlight

F-440 POLYSULFONE MOLDED

- Pipe sizes: 3/8″ , 1/2″ , 3/4″ male NPT

- Flow from: .025 to 5 GPM (0.1 to 37.5 LPM)

- Compact Size – Tight Installations

Description:

- Tough Polysulfone meter body resists high temperatures and pressures

- Compact size for tight installation spaces

- 2” scale length

- In-line or panel mount configurations available (for vertical installation)

- Optional integral flow adjustment valve

- Standard Models: 316 SS guide rod

- K-Series: Hastelloy C guide rod (for corrosive environments)

- Optional: SolarMeter® Brass Adapters

F-450N POLYSULFONE MOLDED

- Pipe sizes: 3/8″ female NPT 1/2″ , 3/4″ male NPT

- Flow from: 0.1 to 10 GPM (.4 to 40 LPM)

- Panel Mount, Adjustable, and Brass Adapters Available

Description:

- Polysulfone meter body resists high temperatures and pressures

- 316 SS or Hastelloy rod guided float

- Taller size for better scale readability

- Direct reading permanent scale

- Optional flow control needle valve

- Not recommended for direct sunlight

- In-Line (vertical) mount only

- Available OEM options: Private labeling, custom calibrations and custom materials

F-451 POLYSULFONE FLOWMETER

- Pipe sizes: 1″ female NPT (Polysulfone) 1-1/2″ female NPT (PVC)

- Flow from: Liquid: 0.5 to 40 GPM (2 to 155 LPM)

- Panel Mount, Sheild, and Brass Adapters Available

Description:

- Polysulfone meter body resists high temperatures and pressures

- 316 SS, PTFE or Hastelloy rod guided float

- Direct reading permanent scale

- Not recommended for direct sunlight

- Available OEM options: Private labeling, custom calibrations and custom materials

- In-Line (vertical) mount only

- Polycarbonate shield available

F-452N POLYSULFONE MOULDED

- Pipe sizes: 2″ F/NPT 2″ socket fusion

- Flow from: 2 to 175 GPM (8 to 675 LPM)

- High Volume

Description:

- Polysulfone meter body resists high temperatures and pressures

- 316SS or Hastelloy rod guided float

- Direct reading permanent scale

- Adapters and unions engineered for increased protection from misalignment and vibration

- Custom calibrations, materials, and Private labeling available

- Very low pressure drop

- Not recommended for direct sunlight

- In-Line (vertical) mount only

- Optional polycarbonate splash shield

ULTRAPURE – Variable Area Flowmeters:

Not Recommended For Direct Sunlight

F-460 POLYSULFONE MOLDED

- Pipe sizes: 1/2″ and 3/4″ female NPT fittings. 1/2″ and 3/4″ socket fusion fittings

- Flow from: .1 to 5.0 GPM (.4 to 20.0 LPM)

- No Metal – UltraPure Applications

Description:

- For use in UltraPure applications

- No metal in the fluid path

- Rib guided float

- Polysulfone meter body resists high temperatures and pressures

- PTFE float and optional PVC, Polypropylene or PVDF adapters for corrosive applications

- Direct reading permanent scale

F-461 ULTRAPURE

- No Metal In Fluid Path

- Molded Polysulfone

- Pipe sizes: 1″ female NPT fittings; 1″ socket fusion fittings

- Flow from: 1 to 35 GPM (4 to 130 LPM)

Description:

- For use in UltraPure applications

- No metal in the fluid path

- Rib guided float

- Polysulfone meter body resists high temperatures and pressures

- PTFE float and optional PVC, Polypropylene or PVDF adapters for corrosive applications

- Direct reading permanent scale

F-462 POLYSULFONE MOLDED

- Pipe sizes: 2″ female NPT fittings

- 2″ socket fusion

- 63mm Butt Fusion

- Flow from: 2 to 80 GPM / 8 to 300 LPM

- No Metal – UltraPure Applications

Description:

- Ideal for corrosive environments such as Deionized Water (DI Water) or other applications where an all plastic meter is desirable

- Designed for in-line installation (Vertical)

- 2” and 63mm Pipe Size

- F/NPT, Socket Fusion and Butt Fusion connections

- Rib Guided Float

- No Metal in the fluid path

- Optional polycarbonate splash shield

- Not recommended for direct sunlight

Delivering The Quality Service You’re Looking For

Our drivers are skilled technicians trained to provide on-the-spot service with the ability to troubleshoot and repair chemical feed equipment in the field.

An inventory of parts and loaner feed equipment are available on our delivery trucks, if needed.

Hawkins and your Sales/Service Representative are available 24 hours a day, 365 days a year to meet your needs. Hawkins has and will continue to aid customers with emergencies that could occur.